Breakthrough! Yixin Welding Completed All Position Automatic Welding of Super Thick Pipe Wall

In June 2020, the Beizhi River comprehensive improvement project entered emergency preparations. The welding of the bottom shaft of the bottom shaft driving flap gate became a major problem in this project due to its ultra-thick pipe wall. Solving this problem smoothly has become the top priority at the moment.

Welding is undoubtedly divided into manual welding and automatic welding: manual welding means ultra-high-intensity human labor and long time-consuming; automatic welding requires extremely high function equipment, which must ensure welding quality and timeliness. Most of the automated welding equipment currently on the market is difficult to achieve ultra-thick pipe wall welding.

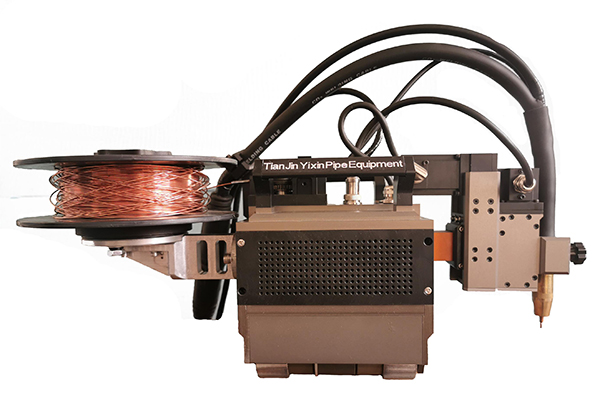

The HW-ZD-200 pipeline all-position automatic welding machine developed by Tianjin Yixin Pipeline Equipment Co., Ltd. is based on the YX-150 equipment. The new angle pendulum function is mainly used for perfect welding of thick walls and narrow gaps.

It makes up for the limitation of welding on thick pipe walls caused by only straight pendulum, plus its more precise control system and automatic return function,

It can also greatly reduce the amount of manual operation and realize the efficient and fully automatic welding of ultra-thick pipe walls. The proposal of a new welding plan quickly won the high attention of the project management.

At the end of June 2020, the Product Quality Standards Institute of the Ministry of Water Resources (hereinafter referred to as the Quality Standards Institute) organized China Power Construction Beiya (Hangzhou) Investment Co., Ltd. (hereinafter referred to as Beiya Company), Hangzhou Asia-Pacific Construction Supervision Consulting Co., Ltd., China Power Construction Group East China Survey and Design Institute Co., Ltd., China Water Resources and Hydropower Sixth Engineering Bureau Co., Ltd., Zhejiang Jiangneng Construction Co., Ltd. (hereinafter referred to as Jiangneng Company) and related experts held a meeting for the upstream sluice and ship lock metal of the Beizhi River comprehensive renovation project Structural manufacturing and installation quality control consulting. The meeting aims to adopt an all-position intelligent welding machine welding method for the on-site circumferential weld welding of the bottom shaft proposed by a new one. It is necessary to provide further welding process qualification, parameter selection, groove form and welding test under the same working conditions.

After this meeting, the welding test plan of the pipeline automatic intelligent welding machine offered by Tianjin Yixin Pipe Equipment Co., Ltd was successfully promoted. The project party transported the target pipeline into Yixin workshop, and carried out the welding test under the condition of simulating on-site working conditions on July 9, 2020.

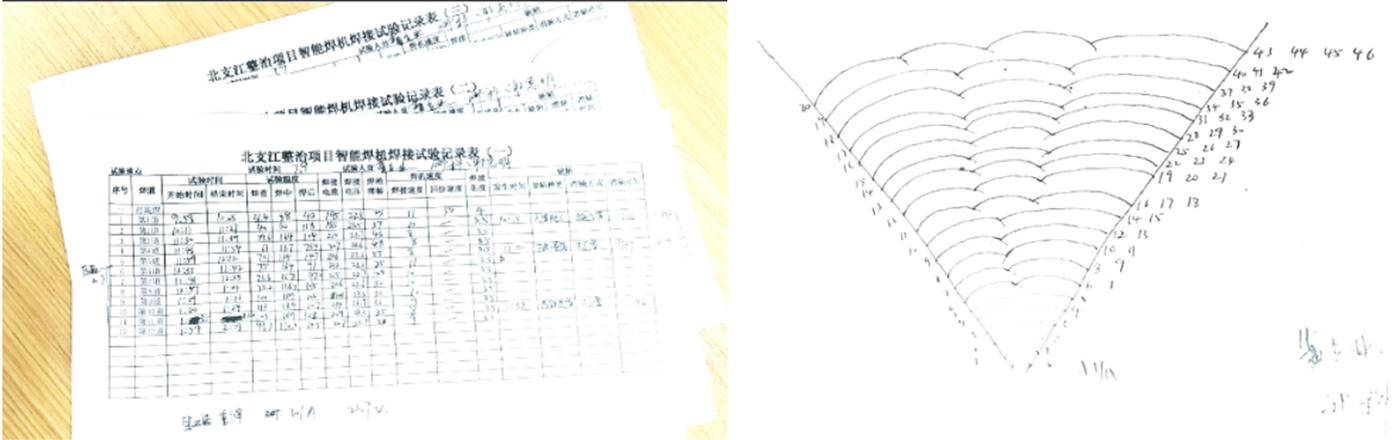

After ten hours of continuous welding, the ultra-thick pipe wall welding test was a complete success and successfully passed the ultrasonic and phase resonance nondestructive testing. The following is the test data collection record:

Pipe details: diameter: 800mm, groove: 35°, wall thickness 85mm, carbon steel material

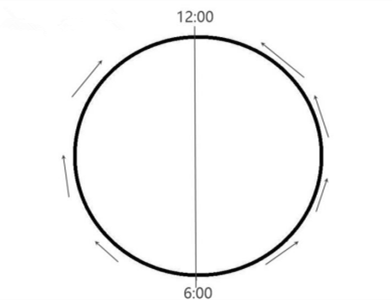

Welding introduction: In this test, 46 layers were welded, including 5 bottom layers, 10 double layers, 27 three layers, and 1 last four layers (welding directions are all from 6 o'clock to 12 o'clock direction).

Root Welding

5 bottom layers,each layer takes on average 7’-8’,

Average time for intermediate adjustment is 4’-5’,

Full time cost for root welding is 1h.

Double-layer Welding

10 double layers,each layer takes on average 7’-8’,

Average time for intermediate adjustment is 4’-5’,

Full time cost for double-layer welding is 2h.

Three layers welding

27 three layers,each layer takes on average 7’-8’,

Average time for intermediate adjustment is 4’-5’,

Full time cost for three-layer welding is 5.85h.

Covering Welding

4 four layers,each layer takes on average 7’-8’,

Average time for intermediate adjustment is 4’-5’,

Full time cost for root welding is 52’.

Onsite Record:

Summary: Through this ultra-thick pipeline welding test, the HW-ZD-200 pipeline all-position automatic welding machine produced by Yixin Pipe Equipment Co., Ltd. utilizes the reasonable transformation of its gun swing and straight pendulum, and more refined intelligent control, stable welding performance and automatic return, etc., perfectly solve the big problem of ultra-thick pipe diameter welding. The successful completion of this experiment is not only a testimony to the strength of a new one, but also a solid foundation for the long-term cooperation between the two parties in the future.

Post time: Dec-20-2020